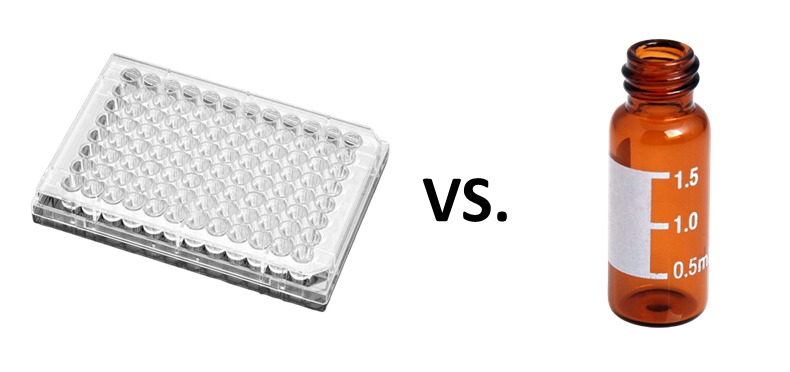

Plates vs. Vials for LCMS: Choosing the Right Format for Your Workflow

Posted by Maxi Scientific on Dec 24th 2024

Liquid chromatography-mass spectrometry (LCMS) is an indispensable tool in analytical science, enabling precise identification and quantification of compounds in complex mixtures. One of the critical decisions when setting up an LCMS analysis is selecting the right sample container—plates or vials. Each format has its advantages and considerations, and choosing the correct one depends on your application, throughput, and experimental goals. Let’s explore the key differences between plates and vials for LCMS, why you might choose one over the other, and the most popular choices in the field.

Vials: Precision and Versatility

Vials are a classic choice for LCMS sample preparation and storage. Typically made from borosilicate glass or polypropylene, vials are compatible with a wide range of solvents and are designed to withstand the pressures and temperatures involved in LCMS workflows.

Advantages of Vials:

- High Chemical Compatibility: Glass vials are resistant to a broad spectrum of solvents, making them ideal for analytes that require aggressive extraction or preservation.

- Ease of Sealing: Screw caps or crimp caps with septa ensure a secure seal, minimizing evaporation and contamination.

- Precision: Vials are perfect for analyses where sample integrity and minimal carryover are crucial, such as pharmaceutical testing or environmental analysis.

Disadvantages of Vials:

- Lower Throughput: Vials are handled individually, making them less efficient for high-throughput applications.

- Space Requirements: They take up more space in autosamplers compared to plates.

Popular Volumes for Vials:

The most commonly used volume for vials is 1.5 mL, often filled with 200-500 µL of sample to ensure sufficient volume for multiple injections while reducing dead volume.

Plates: High-Throughput Efficiency

Microplates, such as 96-well or 384-well plates, are increasingly popular for LCMS applications due to their capacity to streamline workflows. Plates are typically made from polypropylene or polystyrene and are available in various well volumes, from 100 µL to 2mL.

Advantages of Plates:

- High Throughput: Plates allow simultaneous handling of dozens or hundreds of samples, significantly increasing productivity in fields like drug discovery and omics research.

- Automation Friendly: Compatible with liquid handling robots, plates are ideal for automated sample preparation and high-throughput screening.

- Reduced Consumables Cost: Compared to vials, plates are often more cost-effective for large-scale studies.

Disadvantages of Plates:

- Evaporation Risk: Open wells can lead to sample evaporation, especially for volatile solvents, although heat-sealing or adhesive films can mitigate this.

- Limited Solvent Compatibility: Some plates, especially polystyrene ones, may not withstand aggressive solvents as well as glass vials.

- Cross-Contamination Potential: Inadequate sealing or poor handling can increase the risk of contamination between wells.

Popular Plate Formats and Volumes:

The 96-well plate is the most widely used format for LCMS. Wells typically hold 200-300 µL of sample, with 50-100 µL being the most common working volume to minimize waste while ensuring adequate sample for analysis.

Choosing the Right Format

The decision to use plates or vials depends on several factors:

When to Choose Vials:

- Low-Throughput Analysis: Ideal for studies with fewer samples or where individual sample integrity is paramount.

- Challenging Analytes: When working with samples that require high chemical compatibility or when carryover is a concern.

- Specialized Applications: Vials are often the go-to for stability studies, long-term sample storage, or when using particularly aggressive solvents.

When to Choose Plates:

- High-Throughput Applications: Perfect for omics studies, drug discovery, or clinical screening where hundreds of samples are processed daily.

- Automation: Plates are essential for workflows incorporating automated sample handling.

- Cost-Effective Screening: Plates reduce the per-sample cost for large-scale experiments.

The Most Popular Choice

Overall, plates are the preferred choice in high-throughput environments, particularly 96-well plates with a working volume of 50-100 µL. However, for lower-throughput applications or where chemical compatibility is critical, 1.5mL or 2mL vials remain the gold standard.

Got any more questions? Reach out to us at clientservices@maxisci.com or your Concierge!